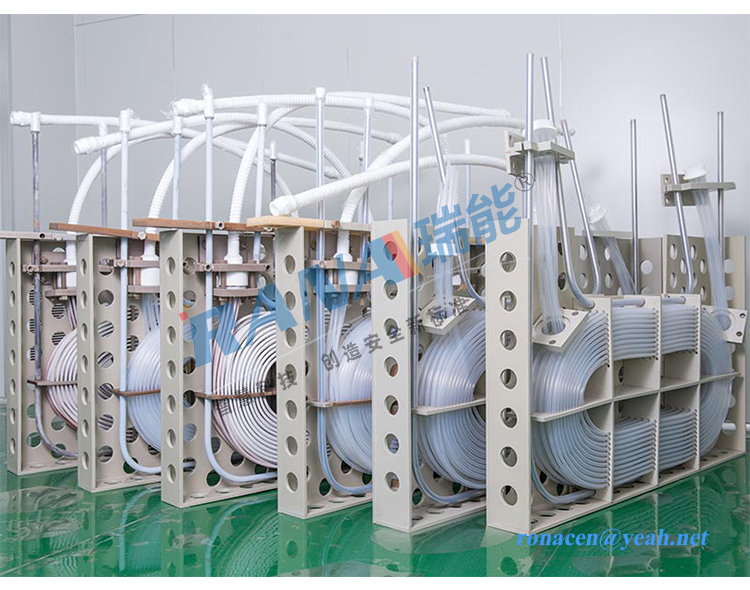

Fluoroplastic PFA Heater RANA specialized in the production of fluorine PTFE GBK sheet, New PTFE GBK sheet, PFA GBK sheet, ECTFE GBK sheet, PVDF GBK sheet, meanwhile, we are the top rank manufacturer of fluoroplastic lined equipment in China. What's more, we also make other fluorine resin products like High Purity PFA Tube,PFA sleeves, PFA welding rod and strips etc. Our products are widely used in aerospace, electronics, chemicals, pharmaceuticals, and other fields.Welcome to contact RANA for more details. exchanger,PFA exchanger,PFA heat Exchanger JIANGSU RANA FLUORINE MATERIAL TECHNOLOGY CO., LTD , https://www.ranatank.com

·Type:

·Media:

·Application:

Centrifugal

Multi-fluid

Suction

·Other characteristics:

·Flow rate:

·Head

Double-aspiration

Min.: 0 m³/h

Min: 0 m

Single-stage

Max.: 11600 m³/h

Max: 200 m

Item

Split case/double suction water pumps

Model

MS

Material

Cast iron, SS 304, SS 316L, etc.

Color

Customizable

Mode

Horizontal

Impeller

Double suction impeller

Drive

Belt or coupling

Seal

Packing seal or mechanical seal

Speed

2950r/m, 1450r/min, 970r/min, 730r/min, 585r/min

Theory

Centrifugal pump

Structure

Single stage pump

Usage

Clean water, raw water, seawater, etc.

Power

Electric motor or diesel engine

Standard

ISO

Application

Plant, mine, power station, urban water supply, irrigation, etc.

Outlet diameter

1 inch to 32 inch

Capacity

25-15000 m³/h

Head

8.6-200 m

Power

22-1250 kW

Warranty

1 year

Certificate

ISO 9001

OEM

Acceptable

Feature

High flow rate, high efficiency, easy maintenance

FAQ:

Q: What kind of company are you?

A: We are a centrifugal pump manufacturer based in Boy Town, Baoding, China, with over 20 years of experience. We have built a strong reputation among our customers for our professional, warm, and thoughtful service. We believe that long-term business is built on quality control, pricing, packaging, and delivery time.

Q: What quality assurance do you provide, and how do you control quality?

A: We have established procedures to check products at all stages of the manufacturing process, including casting, heat treatment, machining, assembly, and testing.

Q: Can you install the motor or diesel engine with the pump for us?

A: Yes, we can. It's no problem, and we have extensive experience in this.

Q: What is your MOQ?

A: Trial sample orders are acceptable.

Q: What are your payment terms?

A: We accept T/T, L/C, D/P, D/A, and more.

Q: What certificates do you have?

A: CE, ISO 2008, UL, and others.

Q: How about the warranty?

A: We offer a one-year warranty for the pump, depending on the working conditions.

Q: What is the delivery time?

A: It usually takes 15–30 days, depending on the order quantity.

Q: Can you do OEM branding?

A: Yes, we welcome OEM orders.

Q: What information should I provide to get a pump solution?

1. Material:

2. Head: ___ m

3. Flow: ___ m³/h

4. Medium size: ___ mm

5. Particle shape (smooth or sharp):

6. Medium pH level:

7. Temperature:

8. Drive type:

9. Power supply:

Contact me for a detailed quotation with performance curves and drawings.

Vicky

Mob: +86 158 3123 7232

Tel: +86 312 8929296

Fax: +86 312 3085383

FAQ:

Q: What kind of company are you?

A: We are a centrifugal pump manufacturer based in Boy Town, Baoding, China, with over 20 years of experience. We have built a strong reputation among our customers for our professional, warm, and thoughtful service. We believe that long-term business is built on quality control, pricing, packaging, and delivery time.

Q: What quality assurance do you provide, and how do you control quality?

A: We have established procedures to check products at all stages of the manufacturing process, including casting, heat treatment, machining, assembly, and testing.

Q: Can you install the motor or diesel engine with the pump for us?

A: Yes, we can. It's no problem, and we have extensive experience in this.

Q: What is your MOQ?

A: Trial sample orders are acceptable.

Q: What are your payment terms?

A: We accept T/T, L/C, D/P, D/A, and more.

Q: What certificates do you have?

A: CE, ISO 2008, UL, and others.

Q: How about the warranty?

A: We offer a one-year warranty for the pump, depending on the working conditions.

Q: What is the delivery time?

A: It usually takes 15–30 days, depending on the order quantity.

Q: Can you do OEM branding?

A: Yes, we welcome OEM orders.

Q: What information should I provide to get a pump solution?

1. Material:

2. Head: ___ m

3. Flow: ___ m³/h

4. Medium size: ___ mm

5. Particle shape (smooth or sharp):

6. Medium pH level:

7. Temperature:

8. Drive type:

9. Power supply:

Contact me for a detailed quotation with performance curves and drawings.

Vicky

Mob: +86 158 3123 7232

Tel: +86 312 8929296

Fax: +86 312 3085383

Sewerage Utilities Double Suction Centrifugal Water Pump

Sewerage Utilities Double Suction Centrifugal Water Pump

Characteristics:

Description:

The S series pumps are single stage, double suction, horizontal split case pumps designed for high volume water transfer across a wide range of applications. These pumps are available in 43 sizes, ranging from 80mm to 400mm discharge, and can handle capacities up to 4000 cubic meters per hour with heads up to 160 meters. The design allows for easy maintenance, with simple assembly and disassembly that doesn’t require special tools. All major wear components and replaceable parts are easily accessible, enabling quick replacement without removing the suction and discharge piping.

Features:

- Adopts a horizontal, vertical axis medium open type double pump shell structure.

- Lining made of cemented carbide or rubber offers excellent wear resistance, corrosion resistance, and high reliability.

- High efficiency hard alloy with low NPSH (Net Positive Suction Head).

- Brief-type structure bearing parts with high bearing capacity design and alloy bearing grease lubrication.

- Adjusting the clearance between protection board and impeller ensures efficient pump operation.

- Uses packing seal, impeller sealing, and container-type mechanical seal to adapt to different operating conditions.

- Pump and drive can be connected via straight league transmission, triangle, hydraulic transmission device, or reducer drive.

- Outflow direction can be rotated at eight angles to suit various site installation requirements.

- Available in multiple series to meet long-distance transmission needs.

Application:

- Fire Protection

- Water Transfer

- Municipal Water Supply

- Irrigation

- Industry

- Process Water

- Raw Water Supply

- Dewatering (Clean Water)

- Flood Mitigation