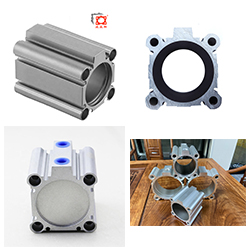

Available bore size: 12, 16, 20, 25, 32, 40, 50, 63, 80, 100mm Cylinder Tube The CQ2 series cylinder is a thin cylinder produced by SMC Corporation in Japan, which is widely used in various mechanical equipment due to its compact design, especially in applications with limited space. Based on the information I have obtained, here are some characteristics of the CQ2 series cylinders: Model and specifications: The model CQ2B500-100 may represent a cylinder with a diameter of 50mm and a stroke of 100mm. CQ2B32-20D may refer to a cylinder with a diameter of 32mm and a stroke of 20mm. characteristic: These cylinders typically have a shorter total length and are suitable for applications with limited installation space. Provide options for different itineraries to meet different application needs. You can choose a version with a magnetic switch installation slot for convenient position detection. Provide multiple installation methods, such as dual ear ring (CDQ2D40-50DMZ). Application: Suitable for application scenarios that require precise positioning and control, such as automation equipment and textile machinery. The damping cylinder version can be used for applications that require smooth motion, such as buffering or speed control. CQ2 Pneumatic Cylinder Barrel,CQ2B Pneumatic Cylinder Barrel,CQ2 Pneumatic Cylinder Tube,CQ2 Pneumatic Cylinder Tubing Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

and has several types: double-acting, single-acting, double rod or adjustable stroke types.

Its compact structure can effectively save installation space.

Its dimension is the same as CQ2, CDQ2, CQ2B, CDQ2B cylinder of other brands.

Study on the Characteristics and Application of Electro - hydraulic Proportional Valve in Construction Machinery

**1. Introduction**

Electro-hydraulic proportional valves are advanced control components that convert electrical input signals into mechanical movement, allowing precise regulation of pressure and flow in hydraulic systems. These valves operate by adjusting the spool position within the valve body, which directly influences the flow and pressure output. The displacement of the spool can be controlled through various feedback mechanisms, such as mechanical, hydraulic, or electronic methods.

Due to their versatility, high control accuracy, ease of integration with electronic and computer-based systems, and strong resistance to contamination, electro-hydraulic proportional valves have found widespread use in various industries, especially in construction machinery. Recent developments in this field have focused on improving performance, incorporating features like pilot control, load sensing, and pressure compensation. These innovations significantly enhance the efficiency and reliability of mobile hydraulic systems. Moreover, the integration of wireless and wired remote control technologies has expanded the application scope of these valves, making them more adaptable to modern automation needs.

**2. Types and Structures of Electro-Hydraulic Proportional Valves in Construction Machinery**

Electro-hydraulic proportional valves come in different forms, including flow control valves, pressure control valves, and multi-way valves. Based on structural design, two main types are commonly used in construction machinery: screw-in cartridge proportional valves and spool-type proportional valves.

Screw-in cartridge valves offer advantages such as easy installation, reduced piping requirements, and lower costs. They are widely used in construction equipment for applications like flow and pressure control. Multi-port versions (two, three, four, or more) allow flexible configurations, enabling complex control scenarios. For instance, a three-way proportional valve can act as a pressure-reducing valve, offering greater flexibility compared to traditional manual valves.

Spool-type proportional valves, also known as distribution valves, are essential in mobile hydraulic systems. These valves manage directional and flow control, often integrated with electronic feedback systems for improved precision. While some models lack built-in sensors due to cost constraints, recent advancements have introduced displacement sensors like LVDTs, enabling closed-loop control and better performance. This evolution is crucial for achieving higher accuracy and stability in dynamic environments.

**3. Load Sensing and Pressure Compensation Technology**

To improve energy efficiency, reduce heat generation, and ensure smooth operation of multiple actuators, modern construction machinery increasingly employs load sensing and pressure compensation techniques. Load sensing adjusts pump output based on system demand, maintaining a fixed differential pressure between the pump and the load. This minimizes energy waste and enhances system responsiveness.

Pressure compensation, on the other hand, ensures that the flow through each valve remains consistent regardless of load variations. By maintaining a constant pressure drop across the valve, it allows for accurate control of flow rate, independent of external loads. Together, these technologies contribute to more efficient and reliable hydraulic systems, especially in complex construction applications where multiple functions must operate simultaneously without interference.

**4. Pilot Control and Remote Operation of Electro-Hydraulic Proportional Valves**

Advancements in electro-hydraulic technology have enabled the integration of electronic control systems in construction vehicles, replacing traditional manual and hydraulic pilot controls. This shift not only simplifies the operator interface but also improves control accuracy and reduces operational complexity.

Remote control systems, particularly wireless ones, have gained popularity due to their flexibility and safety. These systems use joysticks or other input devices to send signals to the valves, allowing operators to control machines from a safe distance. Modern remote control units incorporate secure digital communication protocols, ensuring reliable operation even in challenging environments.

For example, TECNORD’s JMF joystick allows users to control multiple proportional and on-off valves with ease. Its dual-axis design supports both proportional and switch control, making it ideal for complex tasks. These innovations have been successfully applied in various construction equipment, including excavators, cranes, and aerial work platforms.

**5. Application of Electro-Hydraulic Proportional Valves in Engineering Machinery**

A typical example is the hydraulic system of a truck crane, where three TECNORD TDV-4/3 LM-LS/PC proportional multi-way valves are used. These valves integrate load sensing and pressure compensation circuits to optimize pump output and ensure smooth operation. The system selects the highest load signal and adjusts the relief valve accordingly, reducing unnecessary energy loss.

Another example is the bulldozer, where a combination of manual and electro-hydraulic pilot control is used. When the solenoid valves are energized, they direct pilot pressure to the proportional valve, enabling precise control over the machine's movements. This hybrid approach provides the benefits of both manual and automated operation, enhancing overall performance and user experience.

**6. Conclusion**

Electro-hydraulic proportional valves play a vital role in modern construction machinery, offering precise control, energy efficiency, and adaptability. Their integration with load sensing, pressure compensation, and remote control technologies has significantly improved the performance and usability of hydraulic systems. As technology continues to evolve, these valves will become even more sophisticated, further advancing the capabilities of construction equipment. With ongoing research and development, the future of electro-hydraulic control looks promising, paving the way for smarter, more efficient, and safer machinery.

**References**

1. Wu Genmao et al. *Practical Electro-Hydraulic Proportional Technology*. Hangzhou: Zhejiang University Press, 1993.

2. Ruth Swan. "Have you checked out cartridge valves?" *Hydraulics and Pneumatics*, 1991, 8.

3. Danfoss Hydraulic Brochure HK. 51. A3.43, 1997.

4. Delta Power Hydraulic Cartridge Valves and HIC Manifold. Product Brochure, Delta Power Company.

5. TECNORD Company Product Brochure. Address: China Yituo Group Technology Center, No. 39 Xiyuan Road, Luoyang.

CQ2 series compact air cylinder is double acting type Pneumatic Cylinder